On Governors

Introduction

It is possible to observe the cumulative knowledge of the past in the machinery used in ships. One of the devices that have successfully passed the test of time is the governors today can be found in Main and Auxiliary engines. In this essay I would like to address the points that I believe are beneficial to marine operators regarding governors.

Understanding the principles, purpose, and functioning of the mechanism used in maintenance and operation can be beneficial in making informed decisions regarding maintenance practices. I have observed that governors are often in a somewhat misunderstood position for many operators. To provide some assistance in this regard, let us take a historical look at the subject.

History

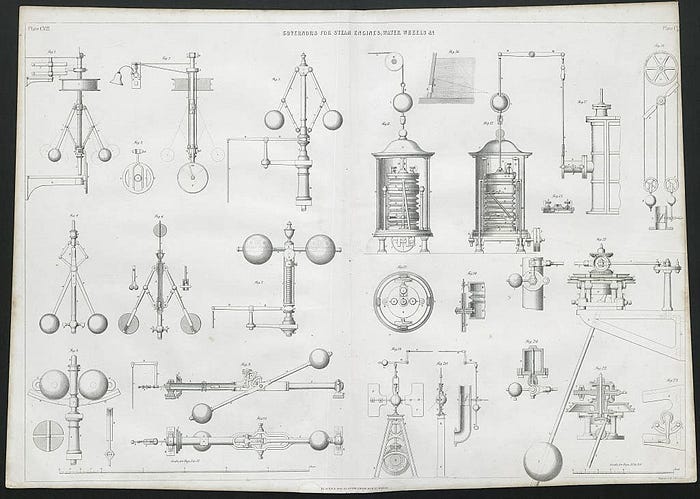

The governor, as a part of the machine, is responsible for maintaining the machine speed nearly constant despite changes in driving power or resistance (3). In modern times, with the incorporation of electronics, this device has evolved into a highly complex structure. Although the simplest form of the governor is commonly attributed to James Watt, the idea of a device controlling the speed of a machine was not his original concept (1). Dutch mathematician, scientist, and astronomer Christiaan Huygens (1629–1695) invented pendulum governors to separate millstones in windmills (1). Approximately a century later, James Watt, one of the pioneers of the Industrial Revolution, improved its design, and governors evolved and remained prevalent in various industrial sectors (4).

In London, at the Holborn Viaduct, there are four statues created by sculptors William Farmer and William Brindley (1). These statues symbolize art, commerce, agriculture, and science (1). The statue representing science holds a Watt-type governor in its hand (1), emphasizing the role of steam turbines and their governors in Britain’s industrial success (1).

The inadequacy of Watt governors was their insufficient response to sudden changes. Machines were prone to a type of oscillating motion known as “hunting” (1). To solve the hunting problem, springs were added to the weights. Between 1860 and 1900, we come across numerous studies and patents related to governors. Examples include Pickering, Tangye, Lumb, Hartnell, and the Swiss Cataract governors (1). Governors have evolved and found their place in various fields, ranging from steam engines to gas turbines, diesel engines, and gasoline engines.

Indeed, it is truly astonishing what humanity has achieved with rotating mechanisms. In almost every rotating mechanism, we encounter a governor that controls the rotation. If there is a rotating mechanism, more often than not, there is also a governor in place to control it.

Governors in Diesel Engines

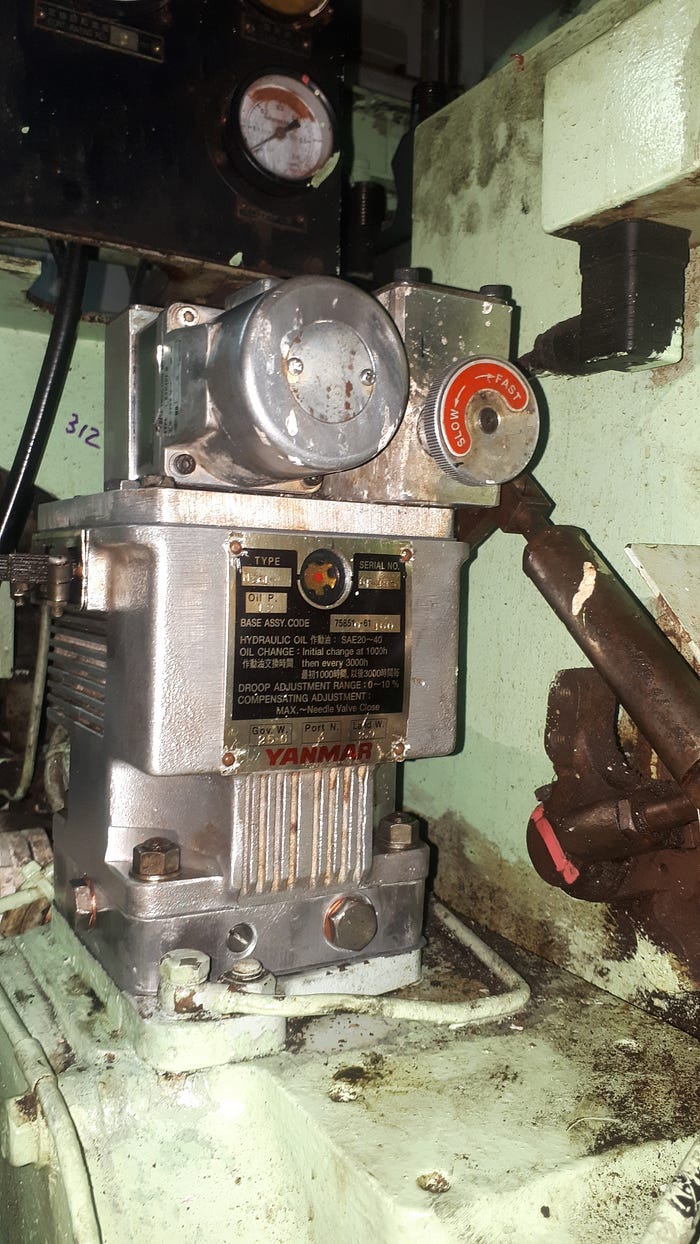

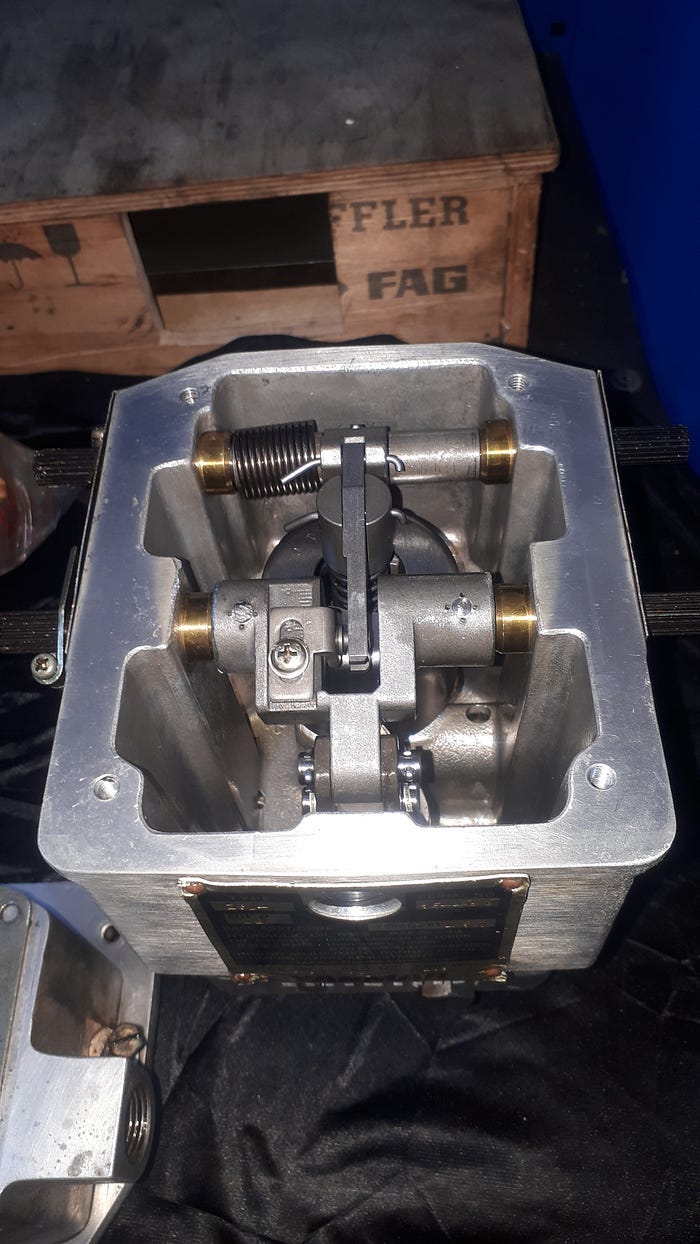

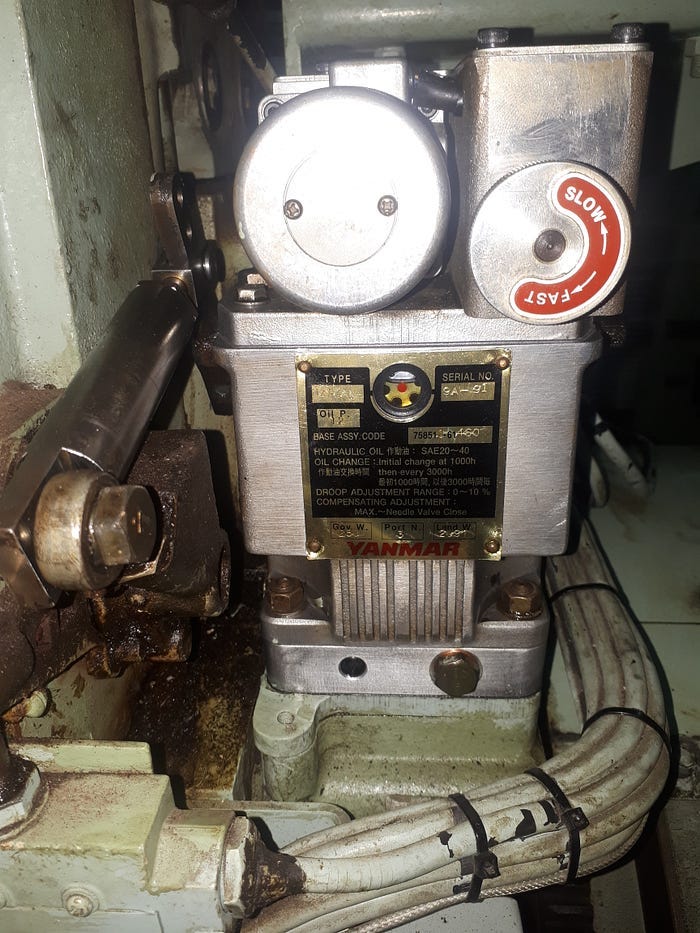

In diesel engines, governors serve the purpose of maintaining the machine at the desired speed (RPM) by adjusting the fuel supply to the engine under certain limits and varying load conditions. They achieve this by altering the position of the fuel racks in the fuel pumps. The governor’s drive gear rotates through a gear on the camshaft, enabling the governor gear to rotate at proportional speeds with the engine. While there may be variations in the internal mechanisms, many governors are controlled through an oil reservoir and an electrical control mechanism on top.

In modern marine diesel engines, many of the governors used are hydraulic governors. It is not advisable for operators to change the governor settings. Making an error in adjustment can cause the engine to operate outside the recommended speed range, leading to destructive damages. So, how should operators take care of the governor?

Tips for Ship Engine Operators Regarding Governors:

In today’s ship engines most governors are of the enclosed type with oil-filled housings. The first thing to pay attention is the oil level and cleanliness in these type of governors. It is important to adhere to the manufacturer’s recommended oil change intervals and use oil of the correct viscosity to prolong the life of the governor.

Based on the information we receive from many ships we service, the most common problem we encounter is usually due to incorrect oil filling. If there is suspicion of oil leakage from the governor, it can be easily checked. The governor can be removed at an appropriate time and placed on a closed container to check if it is losing oil. If the governor is losing oil, it is highly likely that it requires maintenance, and it is recommended to have the maintenance performed by an authorized service provider.

Another aspect to inspect after the oil is the clearance in the pins between the linkage, which connects the fuel pumps and the governor. Over time, these pins and their corresponding pin slots may experience wear, leading to increased clearance. This increased clearance can cause hunting, an unstable movement of the governor that results in inconsistent fuel delivery through the rack arms of the fuel pumps. The excess fuel delivery leads to fuel surges and fluctuations in the engine speed. As the engine speed increases, the governor attempts to reduce the speed by cutting off the fuel, resulting in oscillations due to excessive cutting off caused by the clearance.

If the governor still experiences issues after ensuring clean oil and eliminating clearance in the pins, it is necessary to inspect the fuel system. A malfunctioning injector or fuel pump in one cylinder can also cause hunting. It is not possible to consider the governor independently from the fuel systems. It should be regarded as a whole, and ensuring proper combustion in all cylinders is a prerequisite for proper governor operation.

If all fuel pumps and injectors are new, there is no clearance in the pins, and the governor oil is fresh, but issues still persist, then the electronic or pneumatic systems that control the governor should be examined. The systems that control the governor based on signals from the electrical panel and adjust it according to load changes using air or electric motors need to be checked. At this point, it would be appropriate to call for service specifically for the governor.

Thank you for your valuable time. You can access my other writings from here.

Sources

(1) — The Governor: Controlling the Power of Steam Machines — John Hannavy — https://www.amazon.com/Governor-Controlling-Power-Steam-Machines/dp/1399090887

(2) — https://bilimvegelecek.com.tr/index.php/2019/08/25/bilimin-onculeri-christiaan-huygens-1629-1695/

(3) — Maxwell, James Clerk. “I. On governors.” Proceedings of the Royal Society of London 16 (1868): 270–283.

(4) — https://www.brixtonwindmill.org/about/history/history-in-16-objects/governor/

(5) — https://www.flickr.com/photos/flickyflickr/2789432023

(6) — https://goo.gl/maps/24JdrLqXUqpDPdph9

(7) — https://www.flickr.com/photos/blahflowers/977744166/

(8) — https://www.amazon.co.uk/Victorian-Engineering-Drawing-Governors-Engines/dp/B09B2K8YPR

(9) — https://www.nmes.org/barra.html

(10) —My own personal experiences and shootage

Yorumlar

Yorum Gönder