Importance of Cleaning in Diesel Engines

Introduction

The general principle in internal combustion engines is to convert the thermal energy generated by the combustion of fuel in a closed chamber into mechanical energy. Although different methods, cycles, fuels, and mechanisms are used the underlying principle of the mechanisms is similar. Diesel engines are commonly used in propulsion systems and power generation systems on ships. Extending the lifespan of diesel engines depends on paying attention to certain criteria during operation and maintenance. In this essay I would like to focus on the importance of cleanliness and highlight key points that I find significant. For further reading I recommend Nigel Calder’s book “Marine Diesel engines: Maintenance, troubleshooting, and repair.”

We can say that “cleanliness” is the primary method for extending the lifespan of diesel engines. In diesel engines we can identify four main elements; air, water, fuel, and oil. Air is our source of oxygen which is necessary for fuel combustion. Water is used in heat transfer to maintain the overall temperature of the engine within a stable range and reduce thermal stresses. Fuel serves as our energy source and we use oil to minimize wear and heat generation(friction) between contacting metal parts.

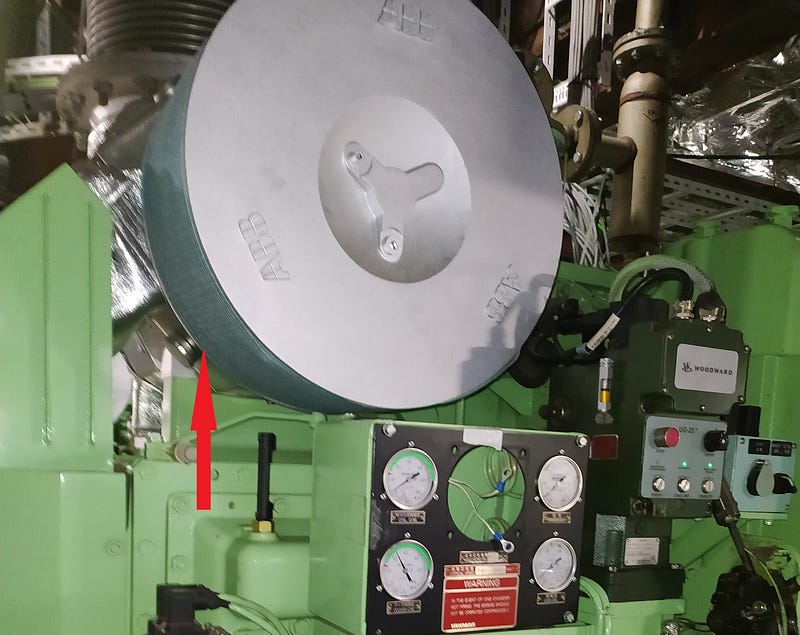

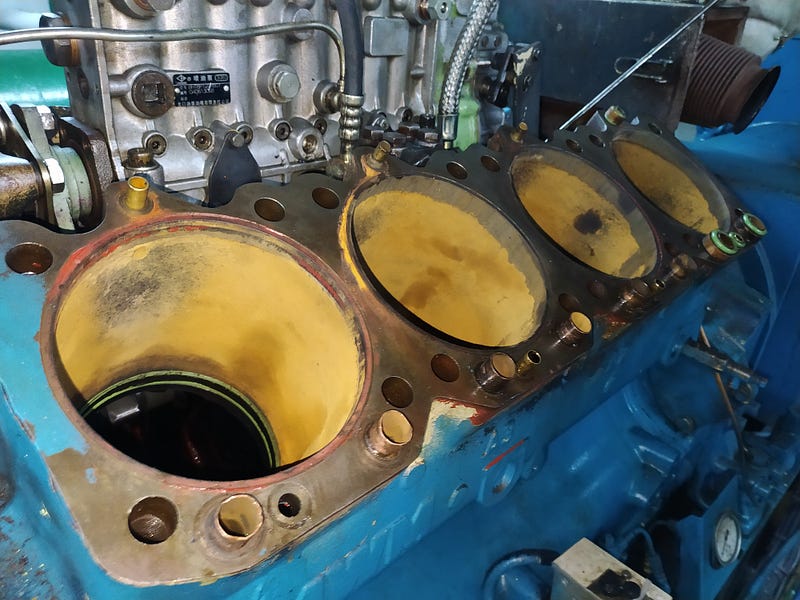

During air intake it is important to have proper filtration and if possible maintain a clean environment where the intake is performed. This is because during the intake process airborne particles can adhere to the cylinder walls increasing wear. Regular cleaning of turbine filters can significantly contribute to extending the engine’s lifespan. The cleaner the air entering the cylinder the less residue and deposits from combustion will occur resulting in reduced wear on engine components and extended life for the combustion chamber elements.

Undesirable particles present in the fuel can lead to an increase in the micron-sized clearance between the barrel and plunger in the fuel pumps resulting in a shorter pump lifespan. Issues with the fuel pump directly affect the combustion process in the cylinders leading to reduced engine efficiency and increased fuel consumption. Additionally the contaminants in the fuel can reach the combustion chamber causing fouling and increased wear on the components. Another undesirable substance in the fuel is water. Water present in the fuel can have a corrosive effect in the cylinders accelerating material wear. It can also disrupt the oil film potentially causing the piston to seize against the liner and resulting in severe damage. Therefore regular cleaning of fuel tanks fuel circuits and all filters in the system as well as the use of water separators in these circuits are beneficial practices for extending the lifespan of diesel engines.

Lubricating oil performs the functions of lubrication and cooling. Periodic oil analysis should be conducted if possible oil should be filtered and the filters should be cleaned regularly. It operates throughout the machine from the main bearings to the rocker arms. Therefore contaminated oil can cause wear throughout the machine. Once again the importance of cleanliness is evident in this aspect.

When components heat up they expand. High temperatures can cause structural damage and decrease the strength of many materials. Additionally excessive temperature changes impose thermal stress on the parts. Therefore dissipating excessive heat from the machine will help prolong its lifespan. This is achieved through the principles of heat transfer. A coolant fluid is circulated within the machine to absorb excess heat which is then cooled by another fluid before being recirculated in the system. However the coolant fluid which is typically water can cause issues such as corrosion cavitation and the accumulation of unwanted deposits. Therefore proper treatment of the coolant is crucial. In diesel engines especially two-stroke engines monitoring and maintaining the chemical properties of the coolant is essential. Test kits are used to monitor specific substances in the water. The desired range is provided by the manufacturer and in order to maintain this range certain chemicals may need to be added to the water. Regularly performing these procedures helps prevent the formation of unwanted deposits ensuring thermal efficiency and extending the lifespan of the machine. Clean water channels and a clean water tank are also important factors in prolonging the machine’s lifespan.

As is seen it is possible to minimize the detrimental effects of dirt on the machine by taking certain precautions. Cleanliness is crucial for reliable and long-lasting operation. Many maintenance practices involve carefully cleaning these components and evaluating them based on manufacturer standards and measurements. In maintenance practices the cleaner the parts the fewer replacements are needed. This will ultimately reduce operational costs in the long run. Cleanliness, a clean environment and clean 4 elements are factors that contribute to the durability of diesel engines allowing them to be used safely for a long time. Thank you for your valuable time.

Sources

[1] — My own experiences and pictures

[2] — Four Elements. Thomas Vogel / Getty Images

[3] — https://marinasional.co.id/product/spectrapak-309-cooling-water-test-kit/

[4] — CALDER, Nigel. Marine Diesel engines: Maintenance, troubleshooting, and repair. International Marine, 1992.

Yorumlar

Yorum Gönder