Diesel Engine Load Management

Introduction

Understanding the interaction between load and efficiency in diesel engines can be beneficial in various ways; from extending the engine's lifespan, reducing fuel consumption to minimizing the environmental impact by reducing harmful emissions and thus contributing to environmental preservation. Shipping plays a pivotal role in global trade carrying a significant portion of the world's cargo. Especially in today's interconnected world where we can shop from anywhere on the planet deeply contemplating the implications of our work, recognizing the significance of our efforts, taking ownership of our work and looking at it from a broader perspective can be valuable in enabling us to do our jobs better.

|

| Efficiency [1] |

If coffee produced in Colombia can be consumed in wordwide and roses grown in Turkiye can be gifted to people all around the world it's all thanks to a well-developed logistics network. To be useful in this network, I believe that thinking about how our work affects this network can increase our dedication.

|

| A container ship berthing [2] |

A dedicated machine operator, maintainer, or marine officer along with the preservation of equipment, primarily enables safe voyages. All the maintenance we perform on equipment or the care we take in operating equipment has the potential to impact the safety of our colleagues who come after us. Moreover, addressing a fault that causes a leak will also mitigate the losses that the leak could cause. Especially considering that we are in the position of consuming petroleum products, we understand that there is an opportunity here to benefit our worldwide wealth.

Repairing malfunctioning equipment properly like fixing a leak prevents excessive spending and yields significant benefits. This is because equipment that doesn't function correctly will affect the entire system and it will be more efficient than equipment that hasn't been maintained. Every drop we save goes towards the employer, our country and even global benefits. Neglected machinery consumes more fuel and emits more harmful gases due to poor combustion. Preventing these issues contributes significantly to environmental conservation in the long run. Through these actions we can realize our potential to be beneficial even to future generations.

A single drop of fuel saved through tightening a bolt can make a significant difference when considering the total operating time. In all our tasks we should strive to act with this awareness and continuously seek to learn for improvement. I believe in the importance of contributing to this effort which is why I wanted to write an article about load levels in diesel engines.

Diesel Engine Load Management

In diesel engines the load refers to the work that the engine is required to perform at a specific time. The load is influenced by factors such as the engine's operating speed, the load on the machine's output shaft or the desired power from the engine. The load of a main engine on a ship varies depending on the weight of the ship, the sea conditions during navigation, and the speed of navigation. In diesel engines that run at a fixed speed like generators the amount of electricity the alternator needs to generate will affect the load.

Indeed proper load management is crucial for efficient and effective operation of diesel engines. Operating the engine within its optimal load range can have a significant impact on fuel efficiency and the engine's lifespan.

When diesel engines are operated at medium to high load levels, they

tend to achieve the most efficient operation. Diesel engines may

struggle to provide the heat and turbine pressure required for proper

combustion at low load levels. This situation leads to increased fuel

consumption and reduced efficiency. On the other hand, very high load

levels can result in increased stress and wear, further reducing machine

efficiency. High loads accelerate wear and shorten the machine's

lifespan.

|

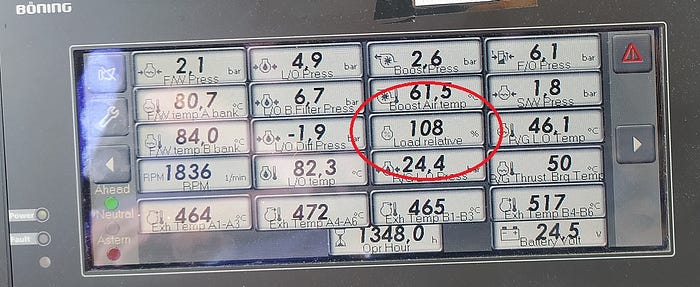

| Monitor of a diesel engine loaded 108% [3] |

Possible Effects of High and Low Loads in Diesel Engines

High Load

Overloading a diesel engine has several adverse effects on its operation. The effects of running at high loads on diesel engines include:

Overheating: High loads can cause the engine to heat up more rapidly, sometimes leading to overheating and damage to internal components.

Increased wear: Engines are designed to operate within a specific load range, and operating outside this range can increase wear on machine elements such as bearings and pistons. Increased load also leads to increased wear and tear on the engine.

Poor fuel economy: Running at a high load can cause the engine to consume more fuel, reducing fuel efficiency.

Low Load

Running diesel engines at low loads also leads to adverse effects. These negative effects include:

Poor fuel economy: When operating at low loads, the engine operates away from its efficient zone, resulting in a decrease in the work energy obtained from the fuel supplied. As a result, fuel economy decreases.

Reduced performance: A machine running at low loads below the optimum loading range will not provide the desired power output, and overall equipment performance decreases.

To avoid all these problems, it is important to know the optimal load range for the machine and ensure that the machine operates within this range, which will contribute to its more efficient operation.

Load Management

The optimal load range depends on various factors such as the size of the machine, its design, the type and size of the vessel, and operating conditions. Generally the range in which diesel engines are most efficient is typically between 70% and 90%. Determining the suitable range for the machine based on the performance curves provided by the manufacturer will be beneficial for achieving the most efficient operation. The graph below [4] represents the performance curve of a diesel engine. When we look at the fuel consumption (denoted as "f") and the load line we can see that fuel consumption is at its minimum at 75% load. When examining the operation manual for a 4-stroke MAN 48/60 engine, we find that the ideal operating conditions are at a constant load within the 60% to 90% load range [5].

|

| Load - Specific Fuel Consumtion Graph [4] |

Conclusion

Understanding the principles of diesel operation is crucial for efficient operation. The load on the machine is one of the most important parameters to follow for efficient operation. Based on our experience, long-lasting, relatively low fuel consumption, and efficiency-focused operation of the machine are achieved at around 70% load. Reviewing the manuals and documents provided by the manufacturer can be helpful in determining the most beneficial load range for the vessel. Thank you for your valuable time. You can access my other articles through this link.

Sources

[1] — https://efficiencyforall.org/wordpress/2018/12/18/efficiency-is-efficient/

[2] — https://premiumcolombiancoffee.com/our-different-services/

[3] — Pictures taken by Myself

[4] — Yanmar 6EY22 Project Guide

[5] — MAN 48/60 Operating Instructions — Section 3.5.4 Part-Load Operation

Yorumlar

Yorum Gönder