Case Study : Changing the direction of the rotation of a diesel engine

One of the rare events for a newly mounted diesel engine has happened. Customer came to us for an unconventional request. They wanted us to change the direction of rotation of two diesel engines. It was quite unusual.

I won’t give the detail why they wanted to change it, but I will share how we did it. Engine specifications are 260 mm bore x 385 mm stroke. Rated output of the engines are 2560 kW. Direction of the rotation was clockwise.

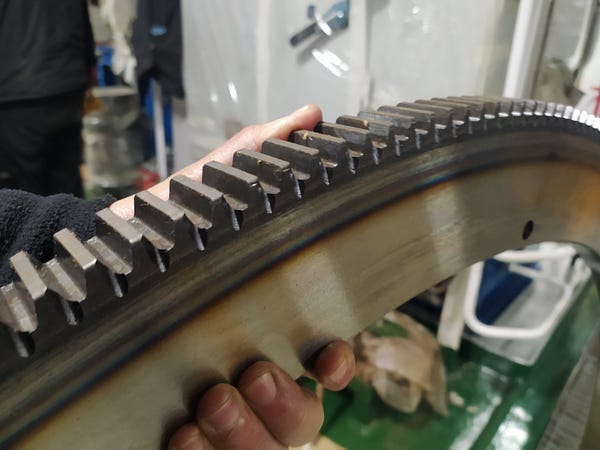

A new direction of rotation means a lot of part will be replaced. First step was to plan the parts that will be replaced. There are built in pumps that driven by the rotation of crankshaft or camshaft. All those movement transmitted via gears. These gears have helix angle according to the rotation. This means a lot of gear replacement will be occured. Starting of the engines are done by air starting motor. New direction means new air starting motor. Finally a new camshaft needed for opposite direction.

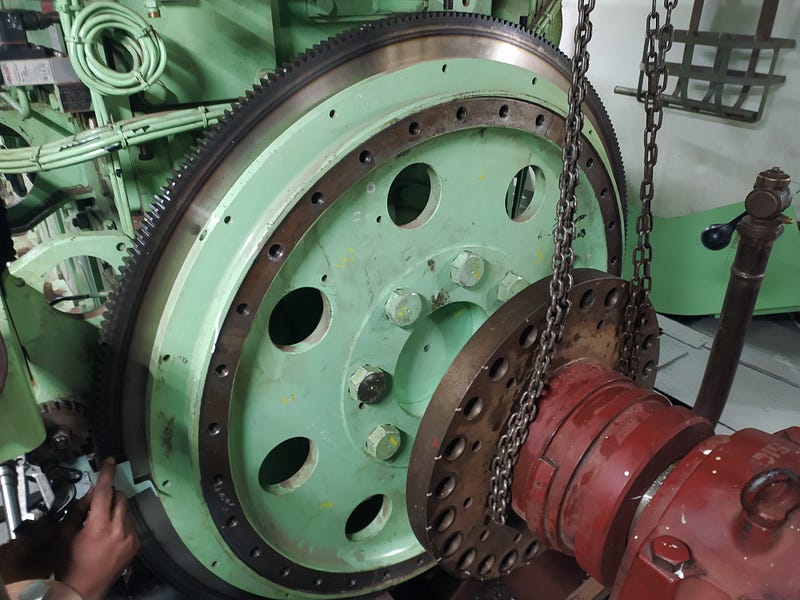

We dismantled flywheels and replaced the flywheel gears.

Starting motors have been replaced.

All parts mounted and we were ready to start and we were excited. We started the engine and the rotation was now counter clockwise.

Yorumlar

Yorum Gönder