Cylinder Heads

Introduction

Indeed, when the term “machine” is mentioned different types of machines may come to people’s minds. However for a seafarer when the term “machine” is mentioned it is highly likely that they will think of a diesel engine.

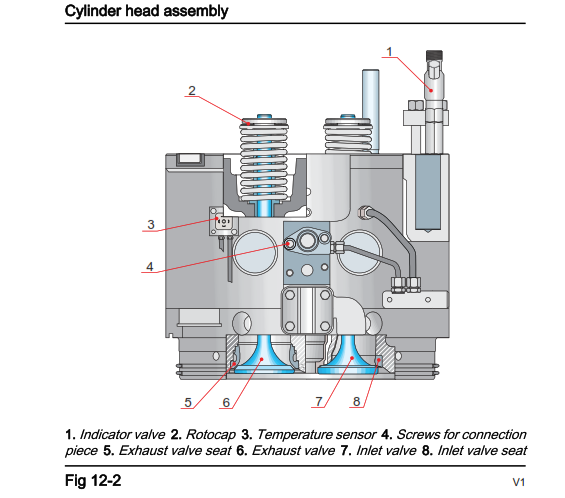

In today’s diesel engines the component that serves as the cylinder’s cover and carries the valves and the seats on which these valves operate is called the “cylinder head”. It can also be referred to as the “cylinder cover” or simply “cover”.

The cylinder head is located at the top of the cylinder in diesel engines. It can be considered as the upper part of the combustion chamber where the piston compresses the air. This is also the area where the issue of “head gasket failure” commonly occurs which is often heard by car owners and those familiar with the industry. The head gasket is located beneath the cylinder head and it can burn out or fail when it reaches the end of its lifespan or is exposed to temperatures higher than its designed operating temperature.

Maintenance

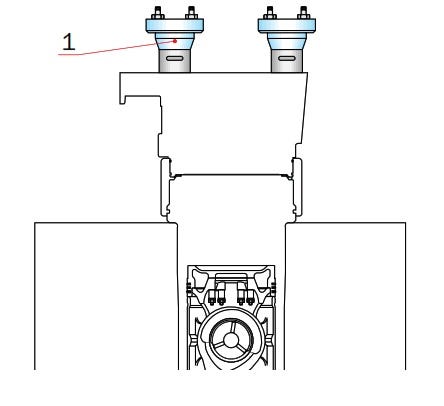

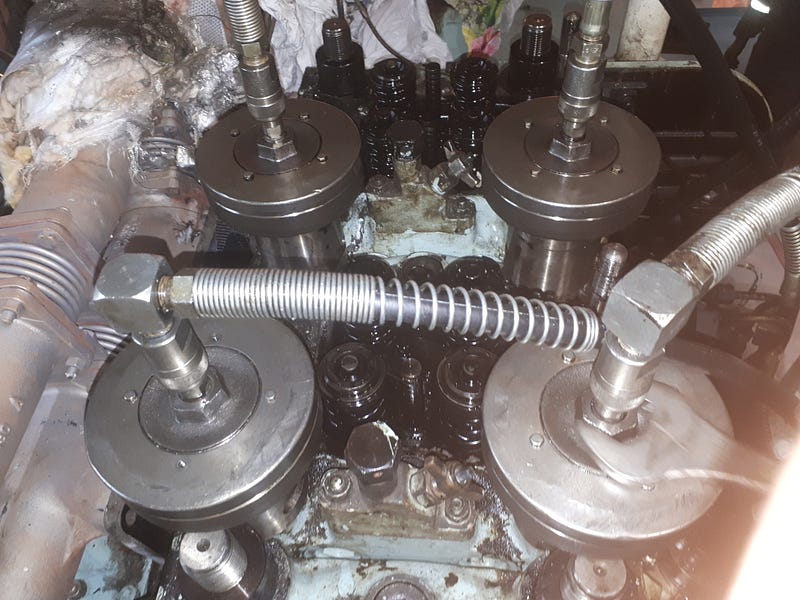

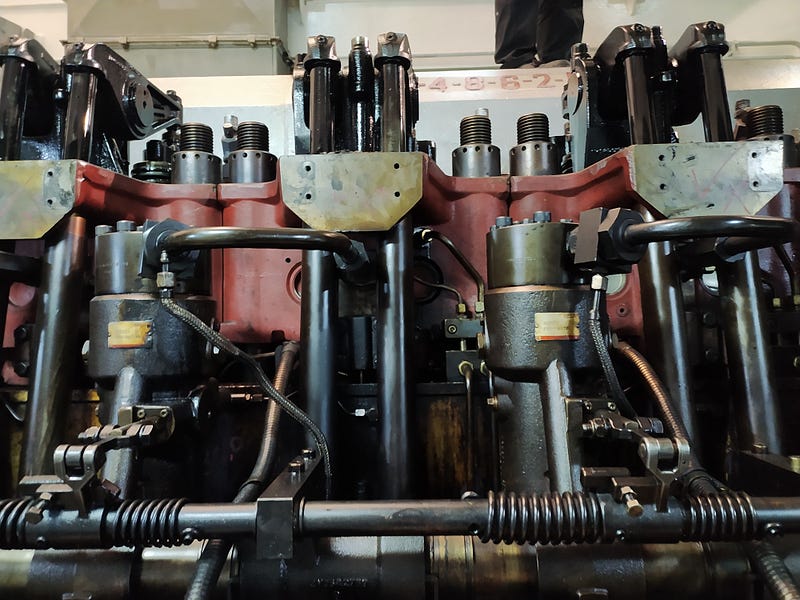

During their career a marine engineer will witness the dismantling and maintenance of the cylinder head or “cover” numerous times. However in most cases more than just ordinary tools are required for the dismantling process. For the removal of the cylinder head hydraulic tools provided by the engine manufacturer are necessary. When the engine is delivered to the ship the manufacturer provides special tools for the ship operator to use. These tools should be utilized for the removal of the cylinder head as well. The answers to questions regarding which tool to use how to set it up and how much pressure to apply can be found in the engine’s instruction book. While it may not take long for a trained eye to find the answers a newly acquainted engineer will need to spend time studying the book to familiarize themselves with the procedures.

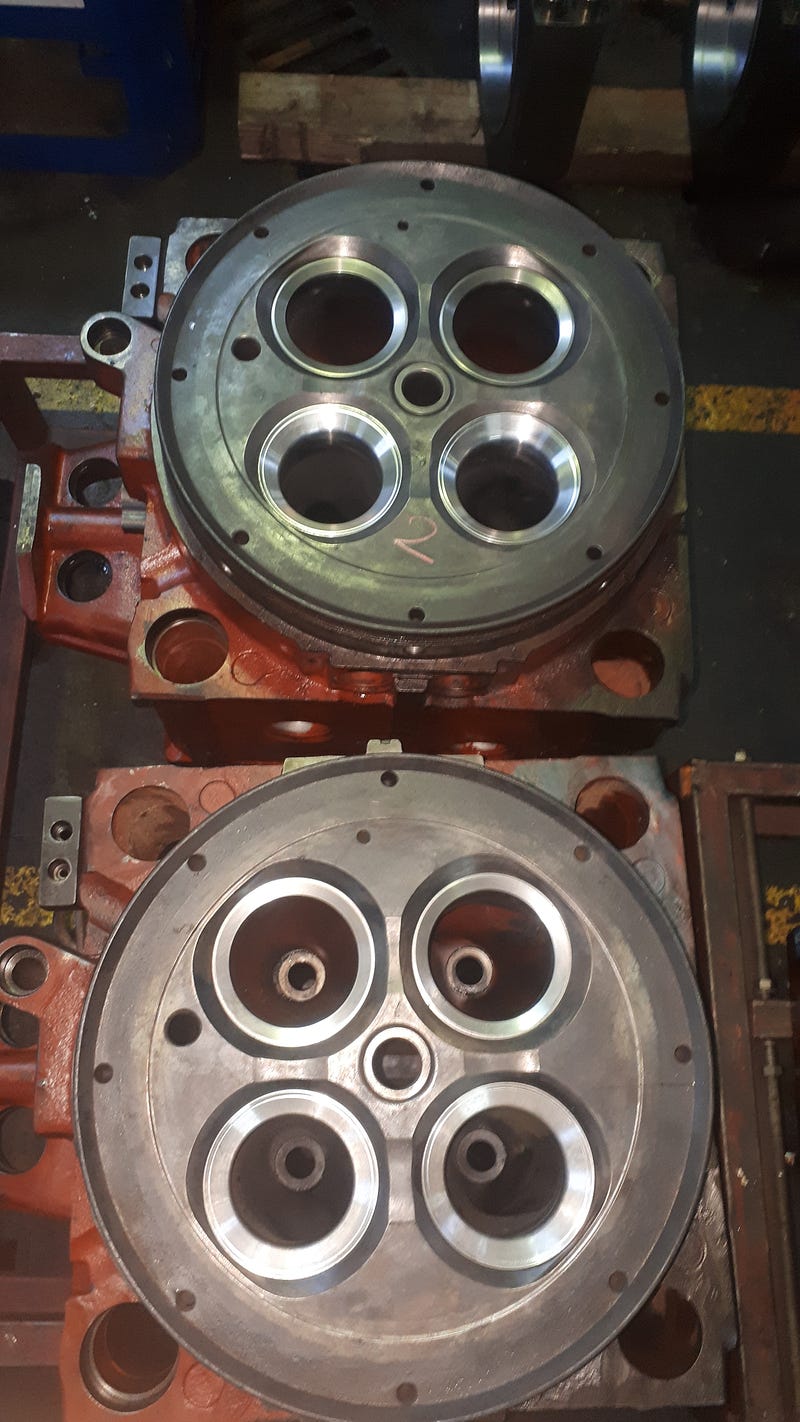

After cleaning, measurements are taken on the valves of the cylinder head, the valve seats which are the surfaces where the valves operate, and the valve guides that enable the up-and-down movement of the valves along an axis. Parts that out of wear limit are replaced with new spares.

Mounting

Once all cleaning, inspection, measurement, replacement, and repair procedures are completed the cylinder heads are ready to mount.

Sources

(1) — Wartsila 8L32 Instruction Manual

Yorumlar

Yorum Gönder