On Cylinder Liners

In diesel engines the combustion chamber is where our piston operates and it's where the air is compressed leading to an increase in pressure and temperature. The walls of this combustion chamber are formed by cylinder liners. In the initial designs, these liners were not present in the cylinder block after a while they were introduced as a solution to extend the block's lifespan. Combustion occurs directly within the liner walls rather than in the block itself.

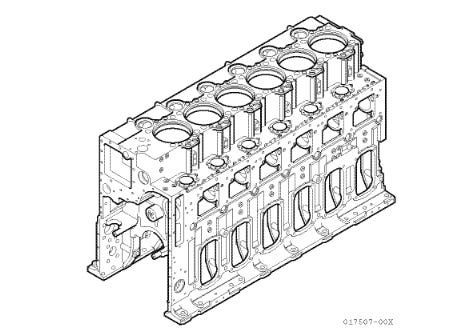

|

| Cylinder Block Without Liner(1) |

|

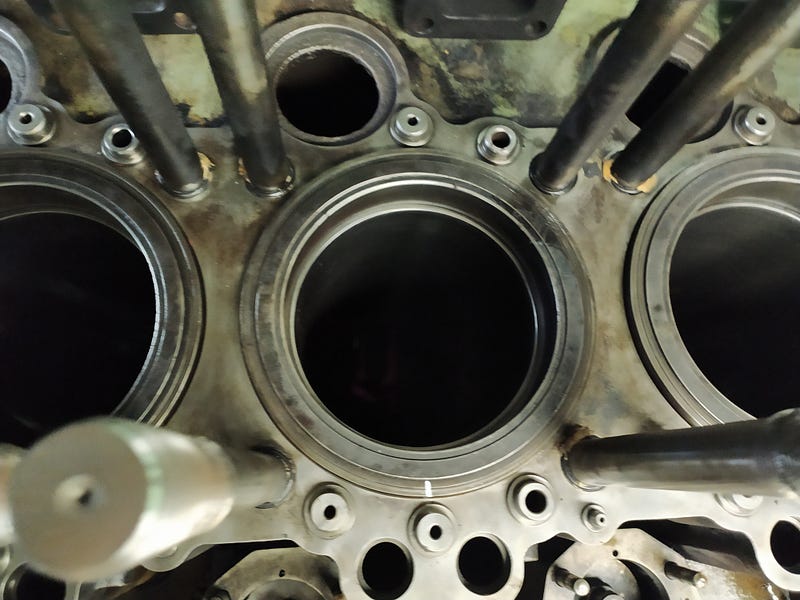

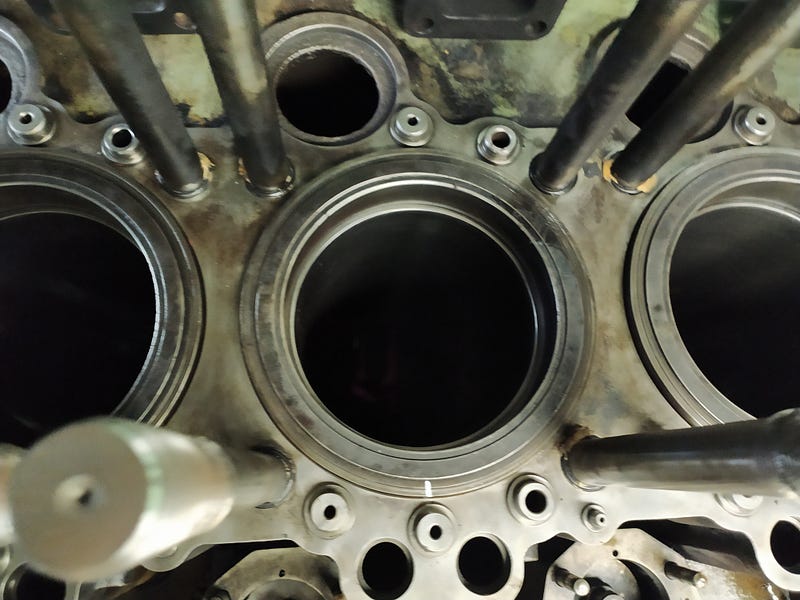

| Cylinder Block With Liner |

In the operation of diesel engines one of the tasks performed during major maintenance is the disassembly, measurement, inspection and honing of liners. Prior to the removal of liners the cylinder covers and pistons must be removed.

For the removal of liners specialized tools provided by the machine manufacturer need to be used. These tools which are often used for methods like pulling for the removal of tightly fitted components enable us to remove the liner in many cases.

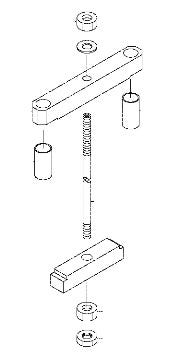

|

| Liner Dismantling Tool (1) |

|

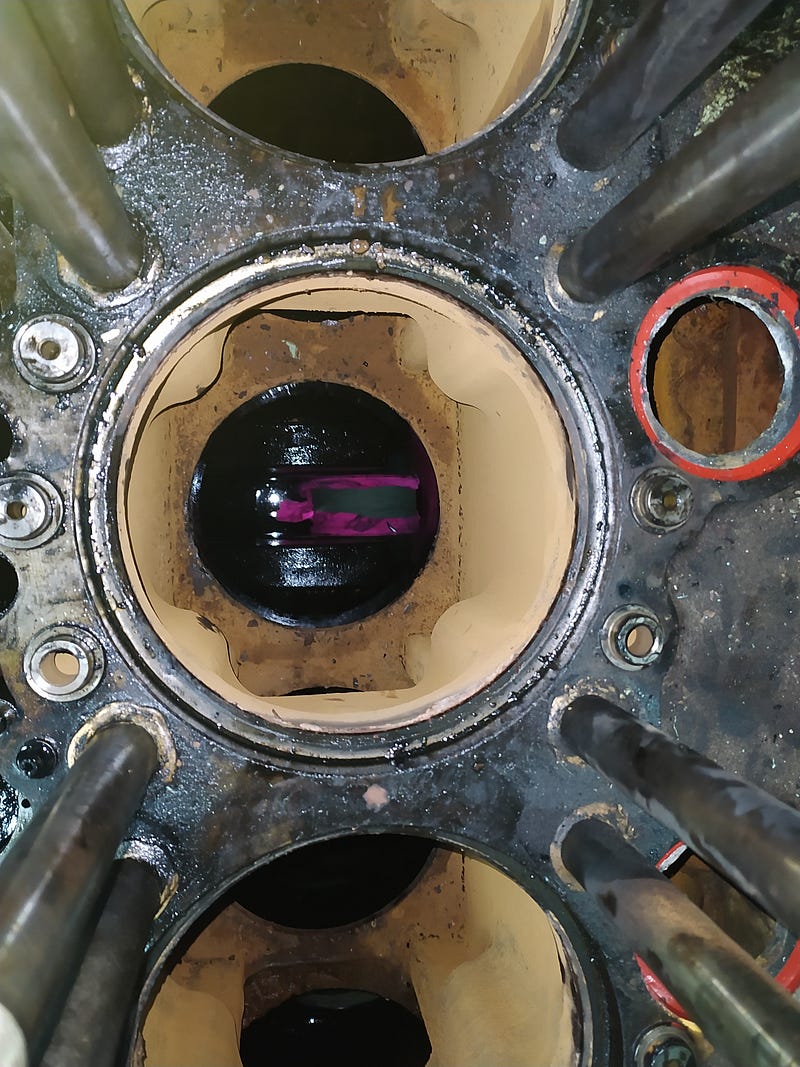

| Liner dismantling with the help of tool |

In many modern diesel engines especially those used in ships there is a circulation of cooling water around the liner and the engine block. During continuous operation when the cooling water is not properly treated a layer called "scale" forms on the block, weakening heat transfer and making the removal of the liner difficult. In some cases even with the use of liner removal tools it may not be possible to remove the liner. The tool's studs can become extended or even break resulting in the liner getting stuck in the block. In such situations hydraulic jacks can be used to remove these tightly stuck liners.

|

A hydraulic cylinder used for the removal of a 2-stroke diesel engine liner. |

|

Cylinder liner removed with the assistance of a hydraulic cylinder. |

After the removal of the liner thorough cleaning and measurement of the inner diameter along the stroke are necessary. The inner surface of the liner is not smooth. To ensure the adhesion of lubricating oils the inner surface is lightly scored at a certain angle. The resulting cross-hatching improves lubrication. It is necessary to repeat this scoring process at regular intervals to enhance the visibility of the cross-hatch lines on the liner. In the industry this process is referred to as honing. Some machine manufacturers provide the required surface roughness value and scoring angle after honing specifying that the honing process should meet this standard.

|

| Honning of a cylinder liner |

|

| Honning scores can be seen |

The liners that have been cleaned, measured and honed are now ready for assembly. Before assembly it is crucial that the block is thoroughly cleaned and the liner seating surface is inspected. In some blocks it may be necessary to check if any previous grinding has been done and to add appropriate shims or shims according to the grinding amount. Checking the Piston Top Clearance and observing the difference between cylinders will provide assurance to the practitioner.

|

| A dirty cylinder block |

|

| Cylinder block after cleaning and checking the set marks matched |

Once the block cleaning is completed the liner sealing elements are installed and the assembly process is carried out. After assembly it can be beneficial to fill water up to the top level of the liner and immediately perform a leak check. If any leakage is observed after installing the piston and cover it may require the disassembly of these components for further inspection.

Thank you for your valuable time.

Sources

(1) — Operation Manual Yanmar 6EY18L

Yorumlar

Yorum Gönder