Case Study : Bridge Valve Breakage

A maintenance worker is never short of surprises in their career. These surprises can sometimes be unpleasant. Just when you think the job is done you realize that everything is actually just beginning. We experienced one of these moments during a machine maintenance when we saw that the pin guiding the cover bridge had snapped. This incident of the bridge guide breaking is a rare occurrence.

One of the components responsible for opening valves in the cylinder heads of diesel engines is a part called the valve bridge, which operates on a solid cylindrical piece. This part is referred to as the "bridge guide."

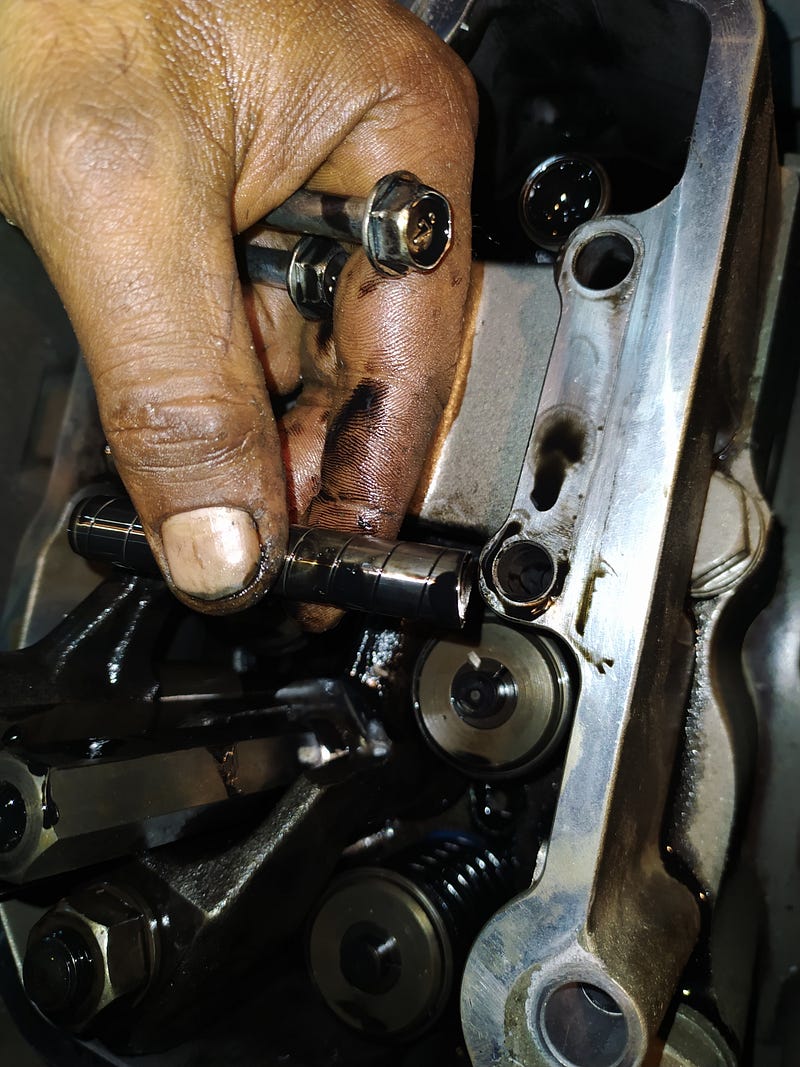

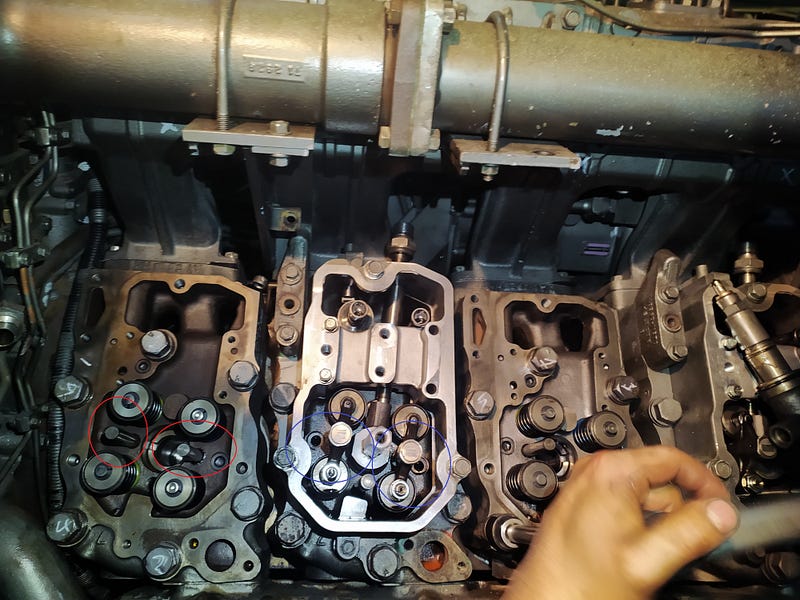

Inside the red circle in the photo, you can see the bridge guide, and inside the blue circle, you can see the valve bridge.

Inside the red circle in the photo, you can see the bridge guide, and inside the blue circle, you can see the valve bridge.For the bridge guide to break the valve bridge needs to operate outside its axis. When a broken bridge guide is detected during routine maintenance the first thing that comes to mind is that the bridge or valve adjustment might have been incorrectly done. However in a running engine valve adjustments tend to tighten over time and if the machine was not adjusted before this scenario becomes unlikely.

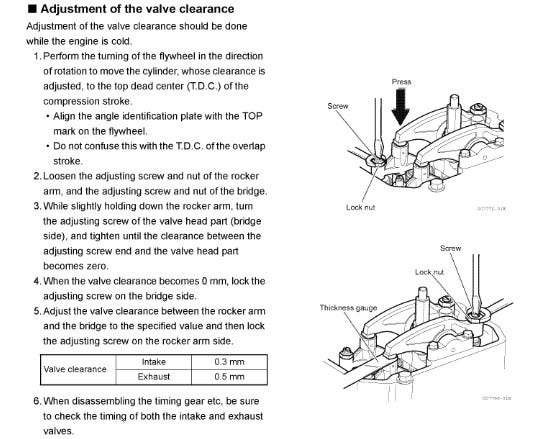

Instructions for Valve and Bridge Clearance Adjustment from a Manufacturer (1)

To identify the source of the problem, all components involved in valve opening need to be disassembled. The parts that need to be inspected include valves, rocker arms, camshaft, rollers and push rods.

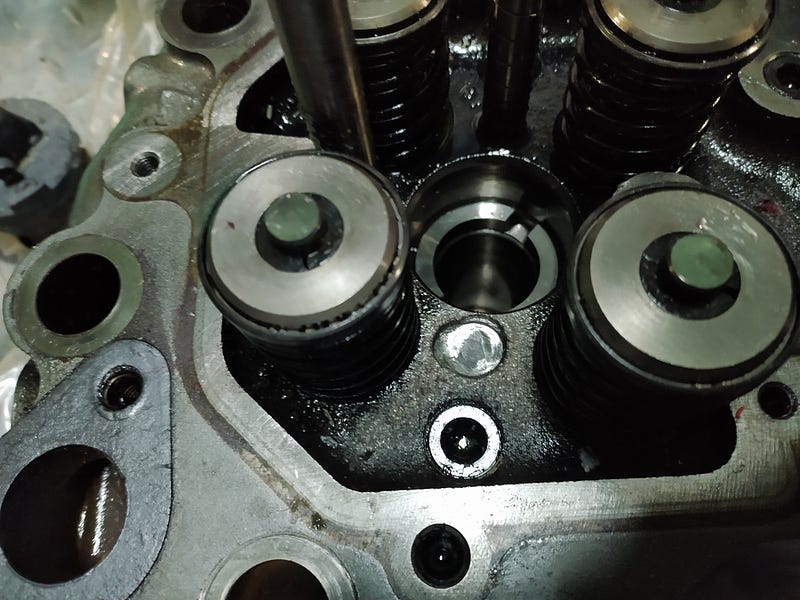

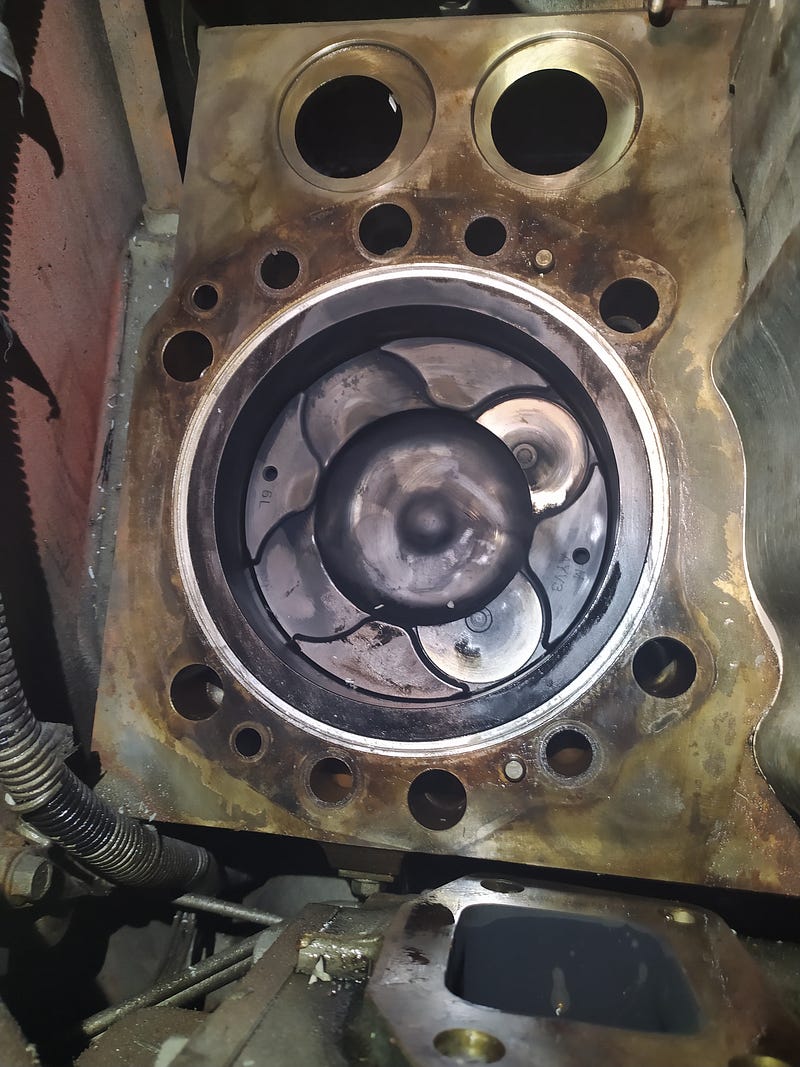

After the removal of the cylinder head valve impact marks were observed on the pistons.

The shiny area observed on the piston is indicative of valve operation

marks. It can be seen that the exhaust side has made contact.

The shiny area observed on the piston is indicative of valve operation

marks. It can be seen that the exhaust side has made contact.The valve striking the piston could indicate an issue with the timing. Since a diesel engine consists of interconnected systems one event can have multiple causes.

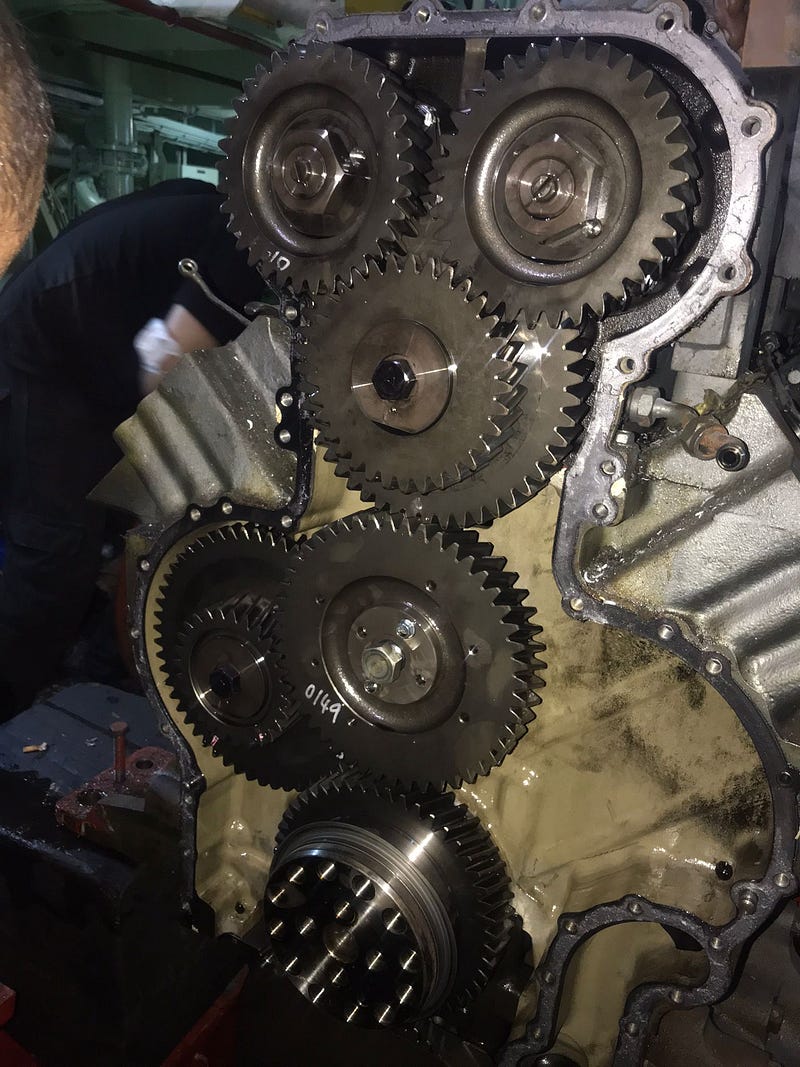

To verify the correct timing the areas where the gears are located should be disassembled. Access to the gears is typically achieved after removing several accessories.

When we opened the gear assembly we noticed that the bolt securing the part that restricts the horizontal movement of the camshaft was loose.

The loosened bolt increased the thrust on the camshaft, resulting in an increased gap between the camshaft and its follower. This gap in a high-speed engine caused the valves to make contact with the piston ultimately leading to the breakage of the bridge guide. When the camshaft gear was removed it was observed that the camshaft key groove was damaged.

Even if we have identified the cause of the bridge guide breakage we may never fully know why that bolt became loose. In a world filled with questions, surprises and uncertainties our profession is no different with each project ending with question marks in our minds, sweat on our foreheads and oil on our hands.

Sources

(1) — Yanmar 12AYM Instruction Book

Yorumlar

Yorum Gönder